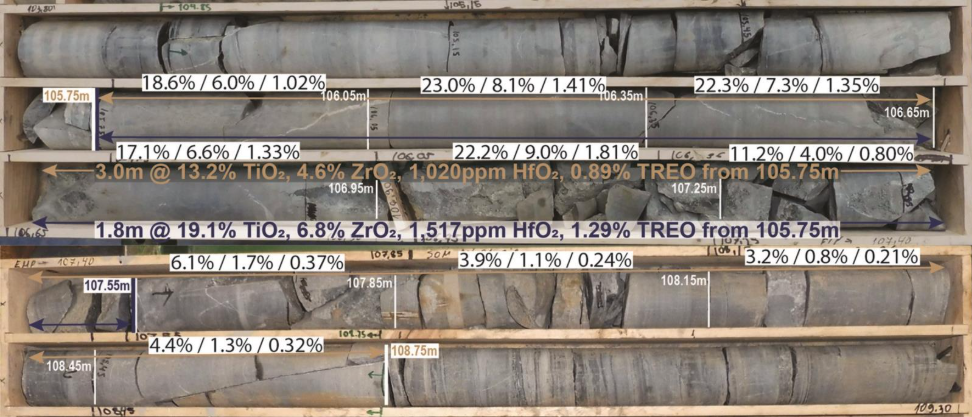

- The company has commenced its initial maiden drilling program with majority of assays pending

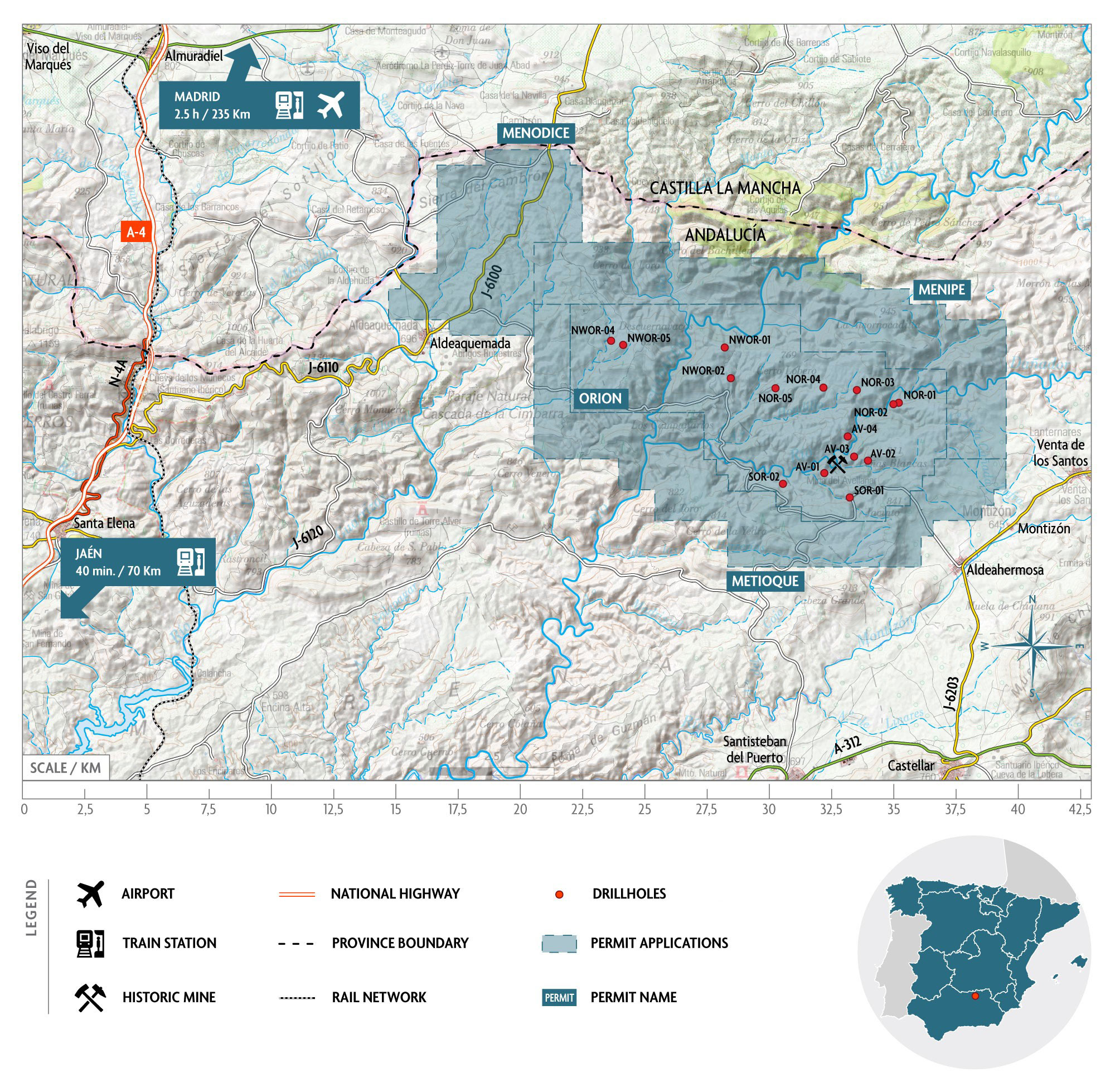

- 756 “cuadrículas mineras” covering an area of ~228km²

- A lithified placer sand geological system with various layers rich in three future facing / critical minerals with high grade potential:

- Rutile (titanium), zircon (zirconium, hafnium), monazite (REE)

- Unsuccessfully explored for uranium and thorium in the 1950’s and 1960’s

- Initial target areas are within Orión Permit

- Historic galena (lead) mine in permit area located directly below mineralised outcrops

- Geological mapping has confirmed two primary seams that appear to be pervasive across the Orión Permit

- Staged acquisition; upon Scoping Study OSM will own 80% of Company owning 95% of the Project*

- *Refer ASX Release dated 29 July 2025

High-Value Potential

- Three Economic Minerals

- Rutile

- Zircon

- Monazite.

High-Tonnage Potential

- 228km2 permit area

- Three target zones

- Mineralised outcrops over 12km distance

- Two interpreted pervasive seams

Drilling Program

- The company has commenced its initial maiden drilling program with majority of assays pending

- Click to view the announcement relating to the AV-01 and AV-01bis drill results on 24 November 2025